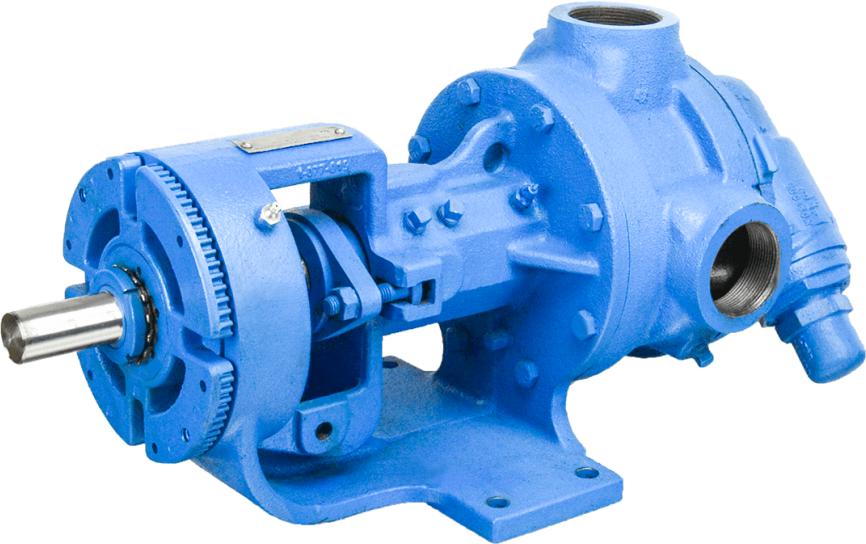

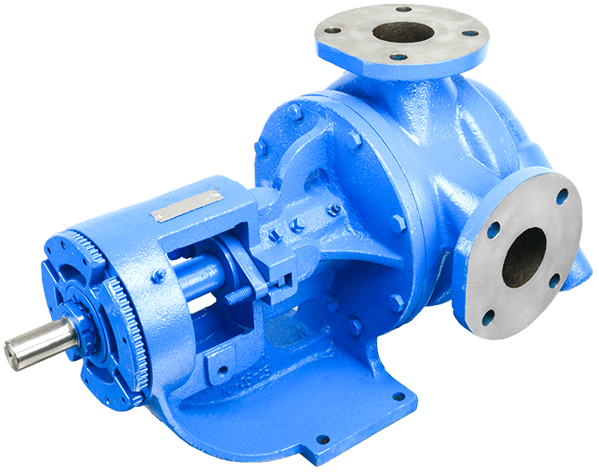

WE ARE THE VIKING PUMP DISTRIBUTOR

for Georgia

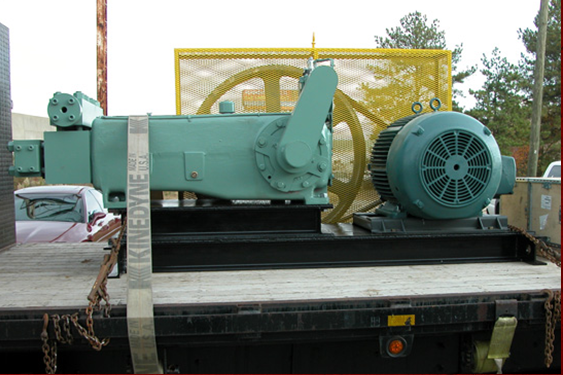

Since 1911, Viking Pump, Inc. has been an industry leader in the world of positive displacement gear pumps. Often imitated but never duplicated, Viking Pump. Inc. sets the standard all other gear pump companies strive to beat. In 1968, Pye-Barker Engineered Solutions was set up as the Georgia distributor for Viking Pump, Inc., and we have been proud to represent them for over 50 years. Viking Pump, Inc. offers innovative solutions for a wide range of demanding fluid-handling applications, and our application engineers have the experience you require to help you get the right Viking pump for your most challenging applications and processes.

VIEW ALL PUMPS