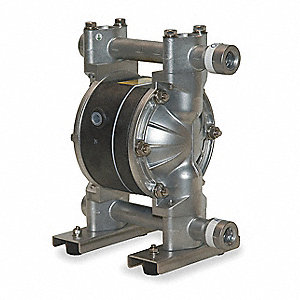

We all love Air-operated double-diaphragm pumps (AODD) because they are easy to operate and inexpensive to repair. However there are some installation traps that will see your new AODD pump not living up to its potential.

AODD Pump Installation Trap #1: Not Installing Your Inlet Line To The Specified Size and Pressure

All too often we hear about AODD pump owners who haven’t installed the specified air line. Usually the installed line is too small (thankfully almost nobody installs a line too large).

When the line is too small, the pump doesn’t have enough power to operate at peak efficiency. And we provide pumps that will operate at peak efficiency based on your system’s requirements. So install the pump to the specifications provided…

To insure your pump gets the required air pressure, we’d recommend installing an air regulator between the compressed air supply line and your AODD pump. Too much back-pressure and you can stall the pump. Too little back-pressure and the pump won’t supply the desired flow at the desired pressure.

So if you want peak performance from your pump then you need constant pressure from your compressed air system.

AODD Pump Installation Trap #2: Failure To Inspect Sealing Surfaces for Leakage

The most common forms of leakage in an AODD pump are loss of torque over time. Over time your pump materials will stretch – this in turn can cause your sealing surfaces to loosen – creating leak paths.

Make sure you replace all your polytetrafluoroethylene (PTFE) O-rings during services. Once your PTFE O-Rings have been compressed they don’t spring back to their original shape. Which means the connection is more likely to leak. Which in turn means unnecessary downtime while you fix it.

O-Rings and maintenance technicians are a bargain compared to unscheduled downtime for critical downstream applications.

AODD Pump Installation Trap #3: Forgetting To Inspect For Muffler Icing And Restrictions.

AODD pumps are loud. This is why everyone recommends installing mufflers during installation. As the air passes from the pump to the muffler it is subject to rapid temperature changes – muffler exhaust is often below freezing – which can cause icing in humid environments.

Keep an eye out for erratic pump oration, humid inlet air or frost on the outside of the muffler – these are all signs your pump is not operating at peak efficiency.

If you have these symptoms, you can try these quick fixes:

That wraps up the first three air-operated diaphragm pump disasters. We’ll be back with part 2 soon. If you have any questions about your existing air-operated diaphragm pumps then get in touch with our team on 404-363-6000 or drop us a line sales@pyebarker.com and we can get your questions answered.