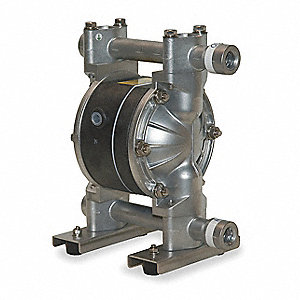

In December, I shared with you 3 Air Operated Diaphragm Pump (AODD) installation traps. There are another 3 common installation traps that I see maintenance teams make when installing them.

I thought I’d share these with you here to save you the time and hassle of having to wait until something stops working on your AODD pumps to go and troubleshoot it and fix it.

A lot of plants choose to use AODD pumps when self-priming is required. If you just switch the air flow from off to the required flow rate, you may find that there is not enough time for the fluid to be drawn into the pump to prime it…

This can be avoided by just turning down the compressed air at the regulator for a few seconds – letting the pump work at the reduced pressure – which allows it to draw the fluid into the pump and prime it.

Then you can turn the pump back to full operating speed.

AODD Pump Installation Trap #2: Ensure Your Tubing and Piping Is The Correct Size

The inlet and outlet ports on your pump are selected based on the flow rate you specify. Make sure your inlet and outlet hoses match the pump’s ports.

The main reason is cavitation. Too little flow to the pump and you’ll end up with cavitation which can ruin a pump in no time flat – leading to costly downtime and repairs. Getting the pipes to match the flow rate is worth the fraction of extra investment upfront to avoid the future problems.

Also – I’d recommend using flexible inlet/outlet piping rather than hard plumbing the pump in. As the pump speed increases the vibration increases which elevates the risk of loosening hard plumbed inlets/outlets – creating a risk of leaks forming.

AODD Pump Installation Trap #3: Clear Fluid Line Restrictions During Maintenance.

Honestly, you’d be surprised how often this step gets missed. We get called in on pumps that have broken down and find all sorts of restrictions in the fluid line. We point this out to the client and they mumble something like - “The maintenance team is supposed to look after that.”

If you’ve got a problem with your maintenance team cutting corners, be sure to inspect them – find out who’s doing their job and who isn’t. Also, it’s not hard for a maintenance supervisor to listen for the tell-tale sound of gravel in the pump or flashing around the manifold elbows which indicate cavitation.

Make sure your maintenance team is checking for

Doing your maintenance is like going to the gym for most people… We hate doing it but we feel better afterwards. If you have any questions about your existing air-operated diaphragm pumps then get in touch with our team on 404-363-6000 or drop us a line sales@pyebarker.com and we can get your questions answered.

Notifications