In 2013, we had a customer in the snack food business. They approached us because they were using sine pumps that they had gotten from Watson-Marlow. They were using these on a peanut butter filling for their snacks. The maintenance manager indicated that these sine pumps were a maintenance nightmare. They were constantly rebuilding the pumps. More importantly, they were getting significant wear on these pumps. The maintenance manager said, “Someone is eating all that metal.”

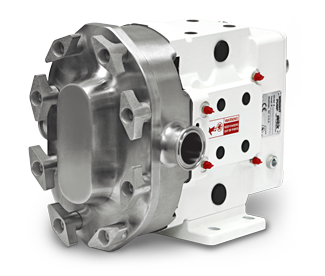

That’s a concern. So we were able to convert his processes and his pumps over to lobe pumps. And these pumps have been successfully operating for them for over eight years now. It’s been quite a success—low maintenance and easy to clean, plus the lack of metal going downstream for this client and for his customers. The last thing we at Pye-Barker want our clients to worry about is how much metal their customers are getting out of their product. In this article, we’ll outline the advantages of lobe pumps.

Please see this article at https://pyebarker.com/5-questions-with-answers-about-rotary-lobe-pumps/

To learn more about this please visit us at pyebarker.com or contact us directly at sales@pyebarker.com

Our Customer Service team is always available at (404) 363 - 6000

Notifications