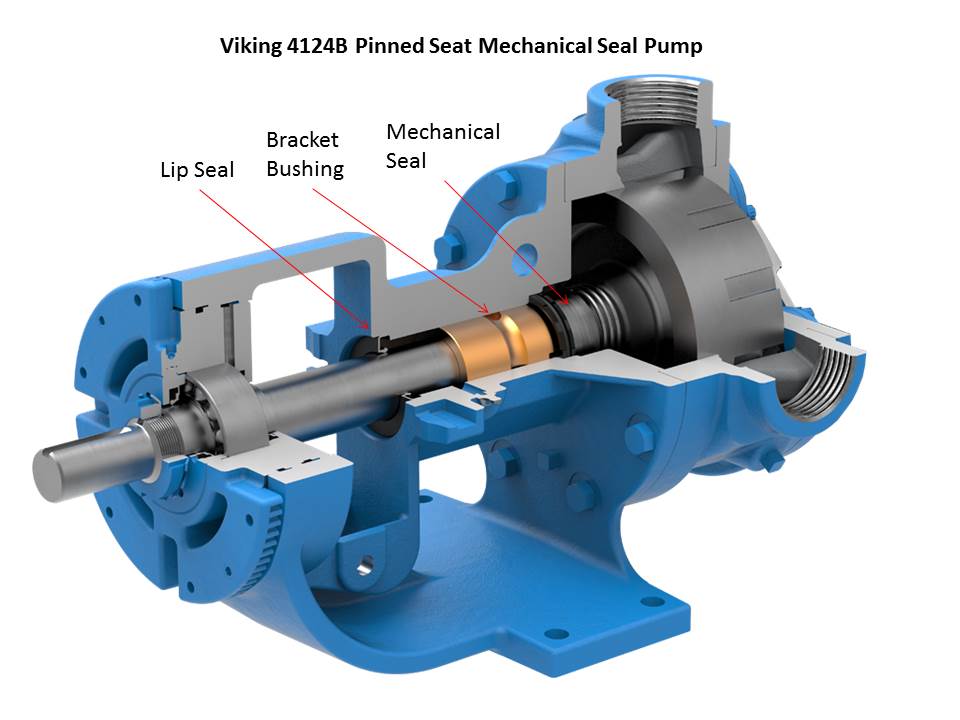

Despite all the advances in pump design over the years, we still have to choose how we are going to minimize leakage from our pumps. Based on our team’s observation here at Pye-Barker, there is a split between two camps. The mechanical seal camp and also the packing camp. Both have their merits depending on the circumstances and no doubt you have your own personal preferences.

I’ll deal with mechanical seals another time and focus on packing here.

From DIY options, to custom solutions to even manufacturer supplied packing systems, any pump buyer is faced with an almost bewildering number of choices.

If you want to pack a pump then there are 4 key steps.

As an authorized service center and supplier of Viking pumps for over 40 years, I want to also share with you a video by Viking on installing packing in your Viking pump.

Choosing the Right Materials.

Since we are in the risk minimization business, we want our clients to maximize up-time, minimize maintenance bills and not spend time and money reinventing the wheel… I believe there are only two sensible choices for pump packing materials. Either use the packing materials provided by the manufacturer that are recommended for your application or use a specialist third party packing supplier. We’ve been using Rainsflo Packing for years on special applications and our clients have been delighted with the results.

Site Preparation.

When replacing the existing packing make sure that the stuffing box is clean. Any debris in there can reduce the quality of the seal and increase the rate of loss from the pump.

Make sure the stuffing box isn’t heavily corroded. If it is, replacing the packing rings won’t give you the seal you desire. You’ll need to replace the worn parts in order to get the same quality seal as you’ve had before.

Correct Installation

Make sure you install your packing as per the manufacturer’s specifications. I won’t get into all of the different ways this can go wrong for you right now. Again, look for a later post on this.

Be very precise about installing your packing. If a component is off, all of your packing might be out of place and again you won’t generate the sealing you are after.

There are a couple of points I’ll address specifically here. Firstly, don’t over tighten your packing. Some product should weep out. If you do, you run the risk of burning the shaft or locking up the pump.

Then. make sure your maintenance team is also aware that packing is meant to weep some product.

Ongoing Monitoring.

During the break in and subsequent monitoring, always follow the manufacturer’s procedures. Again there is nothing worse than doing something twice because you didn’t read the manual. Be sure to allow sufficient run time after each adjustment until you have the system to adapt to your previous adjustment. Once you are happy be sure not to over tighten your packing – remember it should weep. Then continue to follow your packing manufacturer’s guidelines and your packing will have a long life with less downtime.

If you have any questions packing one of your pumps then get in touch with our team on 404-363-6000 or drop us a line sales@pyebarker.com and we will get your questions answered.