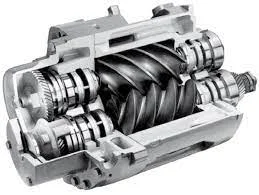

Viking has just stepped up promotion of their new XPD 676 range, so we thought it would be a good time to review their offerings for chemical, petro-chemical oil and gas process applications – the XPD 676 pump series – the first internal gear positive displacement pump to be fully API 676 compliant.

Talking to the team over at Viking they said that designing the XPD 676 pump actually made them re-evaluate their design process and the R&D needed to design a pump to meet the API 676 standard. This has actually had a trickle down effect for how they design the rest of their pump range going forward.

The name of the game in here is risk mitigation. While you can use pumps based on exceptions to the API 676 standard it does mean that you are open to risks and that you must have risk mitigation strategies in place – many of which can be more expensive to enforce than just using a compliant pump in the first place (think air quality litigation, increased cost of insurance, clean up of chemicals or hydro-carbon spills or environmental reporting costs).

Please see this at https://pyebarker.com/product-review-viking-xpd-676-api-compliant-pump/

To learn more about this please visit us at pyebarker.com or contact us directly at sales@pyebarker.com

Our Customer Service team is always available at (404) 363 - 6000

A good air compressor should only be noticed when it isn’t working. The rest of the time it hums away doing its job so that all of your factory’s vital functions can continue on, as expected.

A good air compressor should only be noticed when it isn’t working. The rest of the time it hums away doing its job so that all of your factory’s vital functions can continue on, as expected.

Downtime is frustrating not only because something you expect to work isn’t but also for many businesses we service, an air compressor being down means no product is going out the door.

The downtime is costing you in maintenance and profit as well as upsetting the guys on the floor.

Here are the questions we get asked over and over again about air compressor oil maintenance. Following this advice will save you a fortune in both downtime and repair bills.

Please see this at https://pyebarker.com/longer-life-for-your-air-compressor/

To learn more about this please visit us at pyebarker.com or contact us directly at sales@pyebarker.com

Our Customer Service team is always available at (404) 363 - 6000

A while ago now, we were approached by an engineering firm (who will remain nameless for obvious reasons) to quote on a pumping system for their customer on peanut butter.

The engineering firm had been engaged to design the system and manage the construction project.

Like any good pump supplier we double checked their plans and made sure the specifications were going to deliver the desired outcome. We won the contract to supply the pumps they’d specified for the system.

Please see this at https://pyebarker.com/make-sure-your-pumps-are-put-in-the-right-place/

To learn more about this please visit us at pyebarker.com or contact us directly at sales@pyebarker.com

Our Customer Service team is always available at (404) 363 - 6000

A couple of months back I shared with you three all too common mistakes I see our clients’ maintenance teams make that damage their pumps and shorten their lives, leading to costly repairs, more downtime and unnecessary replacement.

So if you have budget to burn and really want to give us the money to prematurely replace your pumps then by all means do the OPPOSITE of what I’m advising you to do here.

Otherwise – if you want to minimize your downtime and maintenance costs while maximizing the life of your pump then I suggest you avoid these pump ruining ‘tricks:’

Letting Your Pump Run Dry

Don’t do it. When your pump runs dry it can quickly cause pump cavitation and mechanical seal damage – Mechanical seals can get so hot when a pump is running dry that it can shatter in about 30 seconds.

So if a pump is running dry for any reason - shut it off as soon as possible - but RIGHT NOW would be better.

Please see this at https://pyebarker.com/3-more-ways-to-ruin-your-pump/

To learn more about this please visit us at pyebarker.com or contact us directly at sales@pyebarker.com

Our Customer Service team is always available at (404) 363 - 6000

While the vast majority of our customers are looking for a direct replacement for an existing blower, or have engineers designing their new system who have made the calculations to determine the flow and pressure/vacuum required so then all we have to do is match the specs… we still get enough instances where a customer/engineering firm will pick a blower from a catalogue, order it and then complain to us about the results.

If you want to avoid being disappointed with a blower unit you’ve purchased then here are the three most common rookie mistakes:

Picking the Wrong Sized Blower

These clients will often select the smallest blower to provide the flow and pressure they require. This is often at the top end of the flow and pressure curves, and not the optimum performance point.

Please see this at https://pyebarker.com/3-rookie-mistakes-when-selecting-the-right-blower/

To learn more about this please visit us at pyebarker.com or contact us directly at sales@pyebarker.com

Our Customer Service team is always available at (404) 363 - 6000

If you are looking to replace or install an Oil Free Air Compressor, there are several critical factors that need to be assessed when you are evaluating each model.

For those in the know about oil free air compressors – you probably know that not all ‘oil free’ air compressors are 100% oil free. Many traditional makes of oil free air compressors are not actually oil free. They often contain some lubricating oil somewhere… Where there is oil – it can end up in your compressed air…

So to be certain to avoid the risk of oil contaminated air:-

You need to be sure your Oil Free Compressor is actually completely oil free.

Please see this at https://pyebarker.com/buyers-guide-to-oil-free-air-compressors/

To learn more about this please visit us at pyebarker.com or contact us directly at sales@pyebarker.com

Our Customer Service team is always available at (404) 363 - 6000

There has been a radical shift in air compressor technology over the last few years. A lot of the drawbacks of the previous generation of air compressors have been completely eliminated simply by switching to Gardner Denver’s Quantima™ air compressors.

There has been a radical shift in air compressor technology over the last few years. A lot of the drawbacks of the previous generation of air compressors have been completely eliminated simply by switching to Gardner Denver’s Quantima™ air compressors.

The problems with traditional air compressors are – they are expensive to run, need continual maintenance to ensure you don’t end up with a very costly repair bill and aren’t particularly efficient compared to what they could be.

Gardner Denver is confident that by using their new Quantima™ Air Compressors you can easily slash 25% of the total cost of ownership compared to other air compressors on the market. Quantima™ air compressors use Variable rate technology to match output to requirement minimizing off-load running and have the lowest off-load power, just 2.5% of full load power. (That’s 7kW for a 300kW compressor).

Please see this at https://pyebarker.com/breakthrough-air-compressor-technology/

To learn more about this please visit us at pyebarker.com or contact us directly at sales@pyebarker.com

Our Customer Service team is always available at 404-363-6000

When we talk about saving energy we are really talking about saving money – that power isn’t free now is it?

Up to 70% of the total cost of ownership on an air compressor is buying the electricity – it can be less if you buy smart… But it’s a good indication of the lifetime cost of power.

The aim of the game is to use as little power as possible in order to achieve your goals.

Here are some ways to cut your compressed air power bills.

Use the Off Switch

Unless you are a 24/7/365 operation, you don’t need compressed air 24/7/365. Turn your compressor(s) off when you aren’t working. Depending on when you are open you might only need air for 60-100 hours a week rather than the full 168 hours there are in a week.

Turning the thing off when you are shut down could see a 20% reduction in your power consumption.

Please see this at https://pyebarker.com/3-tips-to-save-energy/

To learn more about this please visit us at pyebarker.com or contact us directly at sales@pyebarker.com

Our Customer Service team is always available at (404) 363 - 6000

Historically our clients have been very diligent about installing monitoring solutions for their mission critical pumps. Due to the cost of installing the system and the cost of ongoing maintenance of the system, condition monitoring solutions for all pumps on site has been typically unrealistic.

Manual monitoring of the remaining pumps or a policy of ‘run until breakdown’ is normal which in light of today’s technology can prove to be MORE expensive and unnecessary.

Older monitoring systems meant wiring the sensors into the control center; it was expensive, time consuming and created a lot of infrastructure to maintain.

It meant a limited roll out of electronic condition monitoring to pumps with either a high risk of maintenance issues or a high impact when a maintenance issue does occur. For example – pumps that have repeat failures, pumps without spares or pumps where failure could cause an environmental incident.

Please see this at https://pyebarker.com/3-affordable-monitoring-applications/

To learn more about this please visit us at pyebarker.com or contact us directly at sales@pyebarker.com

Our Customer Service team is always available at (404) 363 - 6000

While the ‘too much’ point for water in a compressed air system varies according to its application, we all know the effects of that water in the system. It can collect in your pipes and equipment where it can cause rust and require premature replacement of the various system components. Additional leaks increase running costs (A single leak may cost you $2,000 per year). Finally water in air means water in your tools damaging them or you end up with air that doesn’t meet compliance standards.

While the ‘too much’ point for water in a compressed air system varies according to its application, we all know the effects of that water in the system. It can collect in your pipes and equipment where it can cause rust and require premature replacement of the various system components. Additional leaks increase running costs (A single leak may cost you $2,000 per year). Finally water in air means water in your tools damaging them or you end up with air that doesn’t meet compliance standards.

Humidity – The bane of air compressors and compressed air systems.

We all know air has water in it – they tell us how much on the news every night when they report humidity. In Atlanta we see an average relative humidity of 82% in the morning and 52% in the afternoon. {https://www.currentresults.com/Weather/Georgia/humidity-annual.php}

Thank goodness for air conditioning, right? The point is there is a lot of water in the air.

Please see this article at https://pyebarker.com/too-much-water-in-your-compressed-air/

To learn more about this please visit us at pyebarker.com or contact us directly at sales@pyebarker.com

Our Customer Service team is always available at (404) 363 - 6000