Viking pump buyers no longer have to rely on mechanical seals or packing for their pumps. Packing breaks down and needs to be replaced. Mechanical seals break down causing leaks. Both packing and mechanical seals require contact with the rotating shaft – which increases wear and tear on the shaft… and causes energy to be wasted in the form of friction.

Viking has developed the O-pro seals to create a robust seal and lubrication chamber all in one. The O‐Pro™ Barrier seal functions as both a seal and bracket bushing.

New Viking pumps can be purchased with O-Pro seals and Viking pumps already in service can be upgraded with an O-Pro seal kit for a simple field retrofit. Available from Pye-Barker Engineered Solutions today.

How Does An O-Pro Barrier Seal Work ON New Pumps?

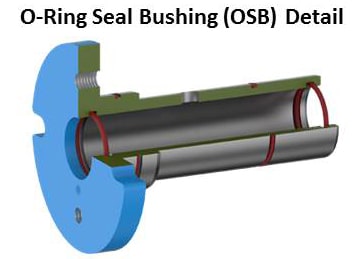

The O‐Pro™ Barrier seal replaces packing and/or mechanical seal by occupying the internal bracket cavity with a machined seal gland utilizing O‐rings to seal externally on the bracket and internally on the shaft. The area between the bracket, gland and shaft are then filled with a lubricating fluid. This combination of O‐rings and lubricating fluid provide a robust seal preventing process fluid from leaking out of the pump, as well as, a lubrication sleeve in which the shaft operates in creating a low wear environment, increasing pump life.

How Does An O-Pro Cartridge Seal Retrofit Onto Existing Pumps?

The O‐Pro™ Cartridge seal replaces packing and/or mechanical seal by sealing the bracket cavity with a machined seal gland that utilizes O‐rings to seal externally on the bracket and internally on the shaft. Internal seal cavity between the gland and shaft is filled with a lubricating fluid. The combination of O‐rings and lubricating fluid provide a robust seal keeping process fluid from leaking out of the pump. The design of the O‐Pro™ Cartridge seal allows for an easy retrofit while addressing the need for stainless‐steel seal construction.

Notifications