At Pye-Barker Engineered Solutions, we help industries across Georgia select the best pumping systems for their operations. One of the most common comparisons we encounter is between lobe pumps and gear pumps. While both are positive displacement pumps, they serve different purposes and excel in specific applications. Choosing the right pump impacts efficiency, maintenance, and overall performance, so let’s take a deep dive into the differences and benefits of each.

At Pye-Barker Engineered Solutions, we help industries across Georgia select the best pumping systems for their operations. One of the most common comparisons we encounter is between lobe pumps and gear pumps. While both are positive displacement pumps, they serve different purposes and excel in specific applications. Choosing the right pump impacts efficiency, maintenance, and overall performance, so let’s take a deep dive into the differences and benefits of each.

A lobe pump is a type of positive displacement pump that uses rotating lobes to move fluid. These pumps are known for their gentle handling of liquids, making them an excellent choice for industries that require sanitary conditions, such as food processing, pharmaceuticals, and cosmetics.

Key Features of Lobe Pumps:

Common Applications for Lobe Pumps:

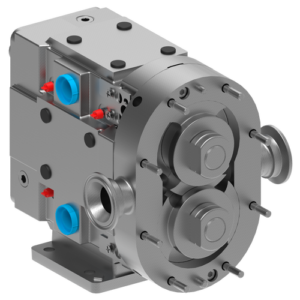

A gear pump is another type of positive displacement pump that relies on intermeshing gears to move fluid. These pumps are widely used in applications requiring high-pressure capability and precise flow control.

Key Features of Gear Pumps:

Common Applications for Gear Pumps:

Fluid Viscosity Handling

Lobe pumps excel in moving high-viscosity fluids, while gear pumps are more suited for low to medium-viscosity applications. If your operation deals with thick substances like molasses or heavy oils, a lobe pump is likely the better choice. For applications requiring precise metering of thinner fluids, a gear pump may be the way to go.

Pumping Efficiency and Shear Sensitivity

Shear-sensitive materials, such as emulsions and biological fluids, require a gentle pumping mechanism. Lobe pumps minimize shear stress, preserving the integrity of the product. Gear pumps, on the other hand, generate higher shear forces, which could impact delicate fluids.

Pressure and Flow Rate Control

When high pressure is a necessity, gear pumps outperform lobe pumps. Industries that require consistent, high-pressure operation—such as hydraulic systems and fuel transfer applications—benefit greatly from the robust nature of gear pumps. Lobe pumps, while effective, operate at lower pressures and prioritize smooth, even flow over forceful output.

Maintenance and Durability

Lobe pumps, with their non-contacting lobes, tend to have longer service lives and require less maintenance. Gear pumps, however, experience more wear due to the constant meshing of gears, leading to a higher likelihood of maintenance over time.

Sanitary and FDA Compliance

Lobe pumps are designed with hygiene in mind, making them the preferred option in food, beverage, and pharmaceutical applications. Gear pumps, although efficient, are not typically designed to meet stringent sanitary requirements.

Cost Considerations

While initial costs vary depending on pump size and application, gear pumps generally have a lower upfront price. However, lobe pumps offer lower long-term maintenance costs, making them a worthwhile investment for industries focused on longevity and hygiene.

At Pye-Barker Engineered Solutions, we work closely with businesses throughout Georgia to provide high-quality pump solutions tailored to their unique needs. Whether you require a sanitary lobe pump for your food processing plant or a heavy-duty gear pump for an industrial lubrication system, our team has the expertise to guide you to the right choice.

We don’t just supply pumps—we engineer solutions. With decades of experience in fluid handling, we provide top-rated equipment, expert installation, and ongoing support to keep your operations running smoothly. If you’re unsure whether a lobe pump or a gear pump best suits your needs, we’re here to help.

Selecting the wrong pump can lead to inefficiencies, increased maintenance, and costly downtime. Don’t leave it to guesswork—trust Pye-Barker Engineered Solutions to help you make an informed decision. Contact us today to discuss your requirements, and let’s find the ideal pump for your business.

Notifications