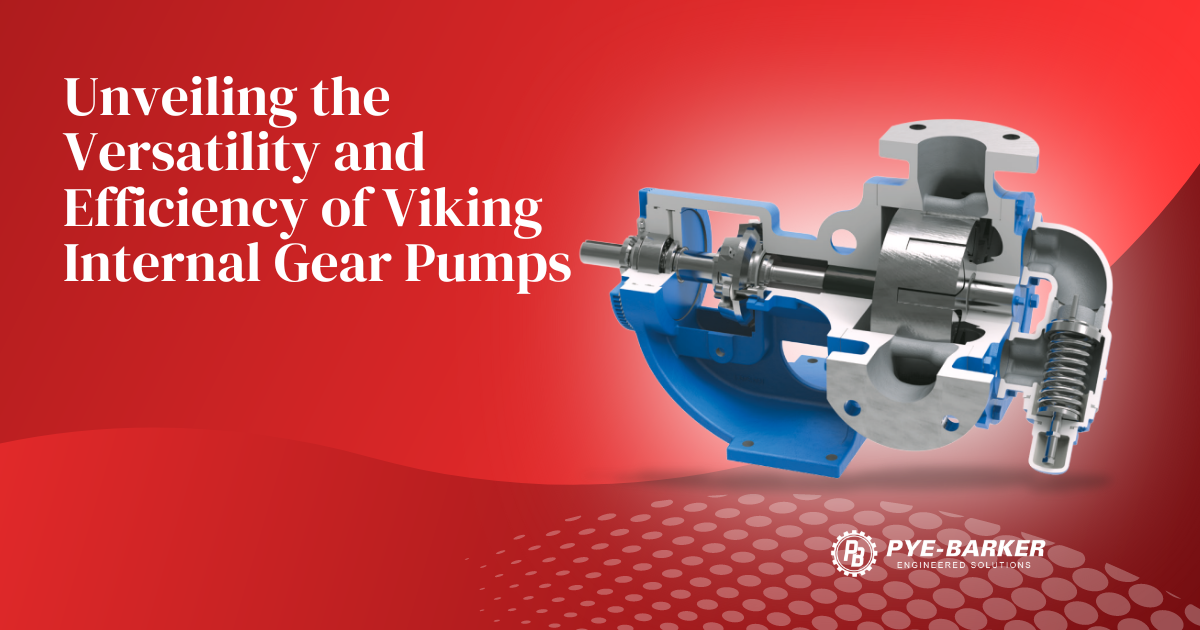

In the world of industrial machinery, efficiency and reliability are paramount. Viking internal gear pumps exemplify versatility and dependability, making them ideal for handling a wide range of liquids, from thin solvents to viscous asphalt and adhesives. At Pye-Barker Engineered Solutions, we explore the intricacies of these pumps to highlight their unparalleled capabilities.

The Power Within: Understanding Viking Internal Gear Pumps

Viking internal gear pumps are renowned for their extraordinary viscosity range, spanning from 1cPs to over 1,000,000cP. This versatility allows them to navigate various liquids seamlessly, ensuring optimal performance across diverse industrial applications.

How Viking Internal Gear Pumps Operate

Liquid Dynamics Unveiled

- Suction Port Entry: Liquid enters through the suction port, guided by the interplay between large exterior and small interior gear teeth.

- Gear-Within-a-Gear Principle: The liquid moves through the pump using the innovative "gear-within-a-gear" principle, maintaining a crucial seal between discharge and suction ports.

- Volume Control: As the pump head reaches full capacity, it expels liquid through the discharge port with interlocking gears ensuring volume control and uniform discharge, regardless of pressure differentials.

- Seamless Discharge: The rotor and idler teeth interlock to create a formidable seal, propelling the liquid decisively out of the discharge port.

Advantages Galore: Unraveling the Benefits of Viking Internal Gear Pumps

Reliability Redefined

- Simplified Maintenance: With only two moving parts and a single stuffing box, Viking internal gear pumps epitomize simplicity and ease of maintenance.

- Non-Pulsating Discharge: Their design ensures non-pulsating discharge and exceptional performance with high-viscosity liquids.

- Operational Adaptability: These pumps operate seamlessly in both directions and require minimal NPSH, showcasing remarkable adaptability in industrial settings.

Tailored Solutions: Applications of Viking Internal Gear Pumps

Viking internal gear pumps find application across a spectrum of industries, including:

- Lube Oils and Fuel Oils: Efficiently handling various oil types.

- Resins, Polymers, and Solvents: Ensuring smooth operation with high-viscosity materials.

- Asphalt, Bitumen, and Tar: Ideal for thick, sticky substances.

- Food Products: Suitable for chocolate, peanut butter, and more.

- Paints, Inks, and Pigments: Providing consistent performance with various liquid media.

- Soaps, Surfactants, and Glycol: Versatile for different chemical compositions.

Consulting the Experts: Your Guide to Optimal Pump Selection

Selecting the ideal pump for your specific needs can be daunting. At Pye-Barker Engineered Solutions, our seasoned engineers are ready to guide you through the selection process. Contact us today to leverage our expertise in Viking internal gear pumps, ensuring peak performance and operational efficiency for your industrial endeavors.

Conclusion

Viking internal gear pumps stand out for their versatility, reliability, and efficiency, making them an indispensable component in various industrial applications. Their ability to handle a wide range of viscosities, coupled with simplified maintenance and operational adaptability, underscores their superiority. Trust Pye-Barker Engineered Solutions to provide the expertise and guidance needed for optimal pump selection and performance.

FAQ

- What is the viscosity range of Viking internal gear pumps?

- Viking internal gear pumps can handle viscosities from 1cPs to over 1,000,000cP, making them extremely versatile.

- What industries use Viking internal gear pumps?

- These pumps are used in industries dealing with lube oils, fuel oils, resins, polymers, asphalt, food products, paints, and more.

- What makes Viking internal gear pumps reliable?

- With only two moving parts and a single stuffing box, these pumps offer simplicity, ease of maintenance, and non-pulsating discharge.

- How do Viking internal gear pumps operate?

- They use a "gear-within-a-gear" principle, maintaining a crucial seal and ensuring uniform discharge through interlocking gears.

Ready to enhance your industrial operations with the unmatched versatility and reliability of Viking internal gear pumps? Contact Pye-Barker Engineered Solutions today to consult with our expert engineers and discover the perfect pump solution tailored to your needs. Call us at [your phone number] or visit our website at [your website URL] to get started.