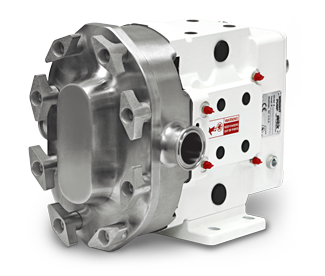

Wright Pump TRA10 in GA: The Best Choice for Sanitary Fluids

The reliability of Wright Flow Technologies positive displacement pumping principle has been proven over several decades. The easy maintenance and robust design make it a great choice for all sanitary fluids. Also, its gentle action on slurries with soft solids or shear-sensitive liquids makes them the preferred technology for all types of beverage, food processing, and cosmetic manufacturing. Today’s post focuses on the Wright Pump TRA10 in GA.

Construction Features of the Wright Pump TRA10 in GA

-

• Rotors are special “Wright Flow Technologies 808®” non-galling, nickel-based alloy.

-

• Powder-coated gear case standard; stainless steel gear case optional.

-

• Pump casing is 316 stainless steel, interior finished.

-

• Seal options include single mechanical seal, double O-ring seal with flush, double mechanical seal with flush, or single O-ring seal.

-

• Four-way mounting allows horizontal or vertical porting and provides mounting flexibility.

-

• Twin wing rotors are standard, with single wing rotors for large solids optional.

• Helical timing gears minimize operating noise.

Typical Applications for the Wright Pump TRA10 in GA

-

• Flavorings: concentrates and syrups

-

• Beverages: mash, wort, fruit juices, fruit concentrate, and beer

-

• Meats: fats, broths, gelatins, pet food, and sausage filling

-

• Dairy: cream, curds, butter, milk, ice cream, soft cheese, yogurt, butter, margarine

-

• Bakery: fruit filling, icing, dough, fats, oils, and yeast

-

• Dressings: Mayonnaise and other prepared sauces

-

• Candy: chocolate, cocoa butter, sugars, gelatin, corn syrup

-

• Industrial: inks, latex, polymers, automotive paints

Main Features of the Wright Pump TRA10 in GA

-

• Exceptional engineering and manufacturing quality.

-

• Parts are interchangeable with other major CPP manufacturer's pumps.

• Time tested and proven circumferential piston design.

Added Value of the Wright Pump TRA10 in GA

-

• SiC/SiC seals instead of carbon/ceramic.

-

• Pump housing dowel pinned and bolted to the gear case.

-

• Powder-coated casing (FDA white, RAL 9003.

-

• One-piece stainless steel shafts instead of welded bi-metal.

• Helical timing gears instead of spur gears.

Unique Cleaning and Maintenance Features of the Wright Pump TRA10 in GA

Aimed at easy strip cleaning, the pump casing is self-sufficiently fastened to the gearbox to avoid damage to the seals when the cover is removed and to permit the rotors to be turned while spraying down the fluid chamber.

The bearing retainers are made of stainless steel, not carbon steel, which ensures a longer lifetime under harsher cleaning conditions. Also, the grease fittings are threaded, to prevent accidental removal during the greasing process.

We are proud suppliers of Wright Pumps. Want to know if the Wright Pump TRA10 in GA is right for your processing environment? Contact us today to speak with one of our specialists!